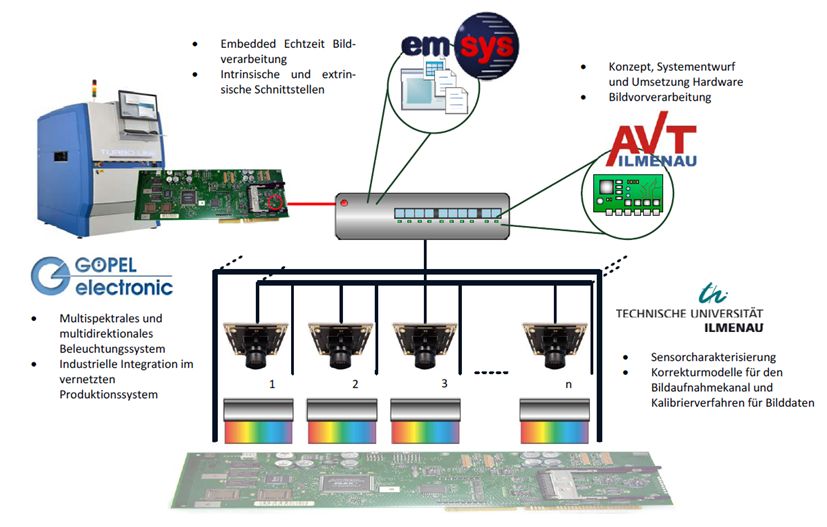

Multi-array image processing system for the inline quality assurance of industrial assemblies (MultiSys)

As part of the development project applied for, an intelligent array camera is to be created, which on the one hand consists of 15 to 30 individual video sensors and, on the other hand, consists of a combination of FPGAs and an embedded PC for the intelligent processing of the extensive amounts of data. As a result of the project, the hardware of the camera array with processing units is to be created as a test sample and the FPGAs are to be programmed for efficient processing. For programming, a close interlinking with EMSYS is in the foreground, since this will show the interfaces between the FPGA program and the software of the embedded PC. In order to be able to set up an efficient system for the array camera, it must be checked in the project which processing steps of the video data should run on the FPGAs and which on the embedded PC.

Sub-project:

Intelligent array camera (INAK)

Necessary work steps for the project:

- Analysis of the task with regard to required and suitable hardware properties, internal and external interfaces, geometric boundary conditions and accuracy requirements

- Hardware evaluation with regard to the required boundary parameters such as resolution, spectral sensitivity and refresh rate for the planned test pattern

- System and interface definitions contain the merging of the internal and external interfaces, which must be coordinated with the project partners

- Programming of the FPGA hardware and image preprocessing, which will run in the hardware design

- When developing the circuit diagram and layout, particular attention must be paid to the high-speed lines of this complex system

- Tests of the array in hardware and program, whereby possibly existing programming errors are to be discovered and eliminated

- n in-system test with the project partners confirms the functionality of the demonstrator. An important result here is the verification of the algorithms as a black box, i.e. the behavior on specified processes. This is done with the help of real data. The findings from this stage provide data for a final fine-tuning of the parameters. The parameter adjustment represents an optimization of the demonstrator.